BATCH TYPE CENTRIFUGAL MACHINES

High grade, flat bottom machines incorporate excellent self supporting mechanical designs with latest updated electrical driving & control systems. Suspension assembly & basket designed for high-in built stability to meet any imbalance effects.

ADVANTAGES

- Higher gravity factor ensures effective purging of massecuite, optimizes wash water consumption and run-off quantity.

- Special designs allow construction of lighter basket requiring lower driving power.

- Effective separation of heavy and light run-off molasses avoids circulation of sugar and helps in process balance.

- Elimination of steam drying increases crystal yield and reduces bagging temperature of sugar.

- Minimum space requirement and fully assembled machine construction hence lower installation time and costs.

We offer a wide range of machine models ranging from 500 Kg/Ch. to 1750 Kg/Ch. with technical specifications as under,

|

PARTICULARS

|

MODEL YB 500

|

MODEL YB 750

|

MODEL YB 1000

|

MODEL YB 1250

|

MODEL YB 1750

|

|---|---|---|---|---|---|

|

Nominal Filling Capacity (kg/charge)

|

500

|

750

|

1000

|

1250

|

1750

|

|

Basket Inside Diameter (mm)

|

1250

|

1250

|

1200

|

1300

|

1600

|

|

Basket Inside Height (mm)

|

650

|

800

|

1000

|

1067

|

1100

|

|

Basket Material Specification (moc)

|

Special high tensile strength resistance, special chloride resistance, anti-corrosive & food grade stainless steel quality material.

|

||||

|

Basket Speed (rpm)

|

1440

|

1440

|

1250

|

1250

|

1150

|

|

Installed Motor Rating (kw) in DC/AC Drive

|

90/120

|

110/160

|

110/160

|

135/200

|

145/250

|

|

Max. Centrifuge Effect (g)

|

1450

|

1450

|

1049

|

1136

|

1183

|

|

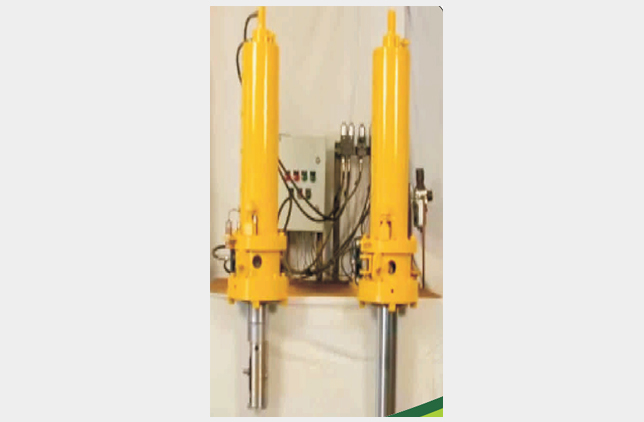

Machine Lubrication System

|

Bearings are lubricated by Grease/Oil mist lubrication to ensuring low bearing temperature rise.

|

||||

|

Number of Cycles per Hour in DC/AC Drive Machine Control System (minimum)

|

20/24

|

20/24

|

20/24

|

20/24

|

20/24

|

|

Power Consumption in DC/AC Drive (kwh/cycle)

|

1.0/0.7

|

1.0/0.7

|

1.0/0.7

|

1.2/0.8

|

1.2/0.8

|

|

Capacity of Machine for “A” or High Grade Massecuite Curing in DC/AC Drive (TPH)

|

10/12

|

15/18

|

20/24

|

25/30

|

35/42

|

Capacity & number of charges subject to massecuite quality, type of drive & requirement of process results etc.

The above machines can also be supplied in SS construction of food grade quality.

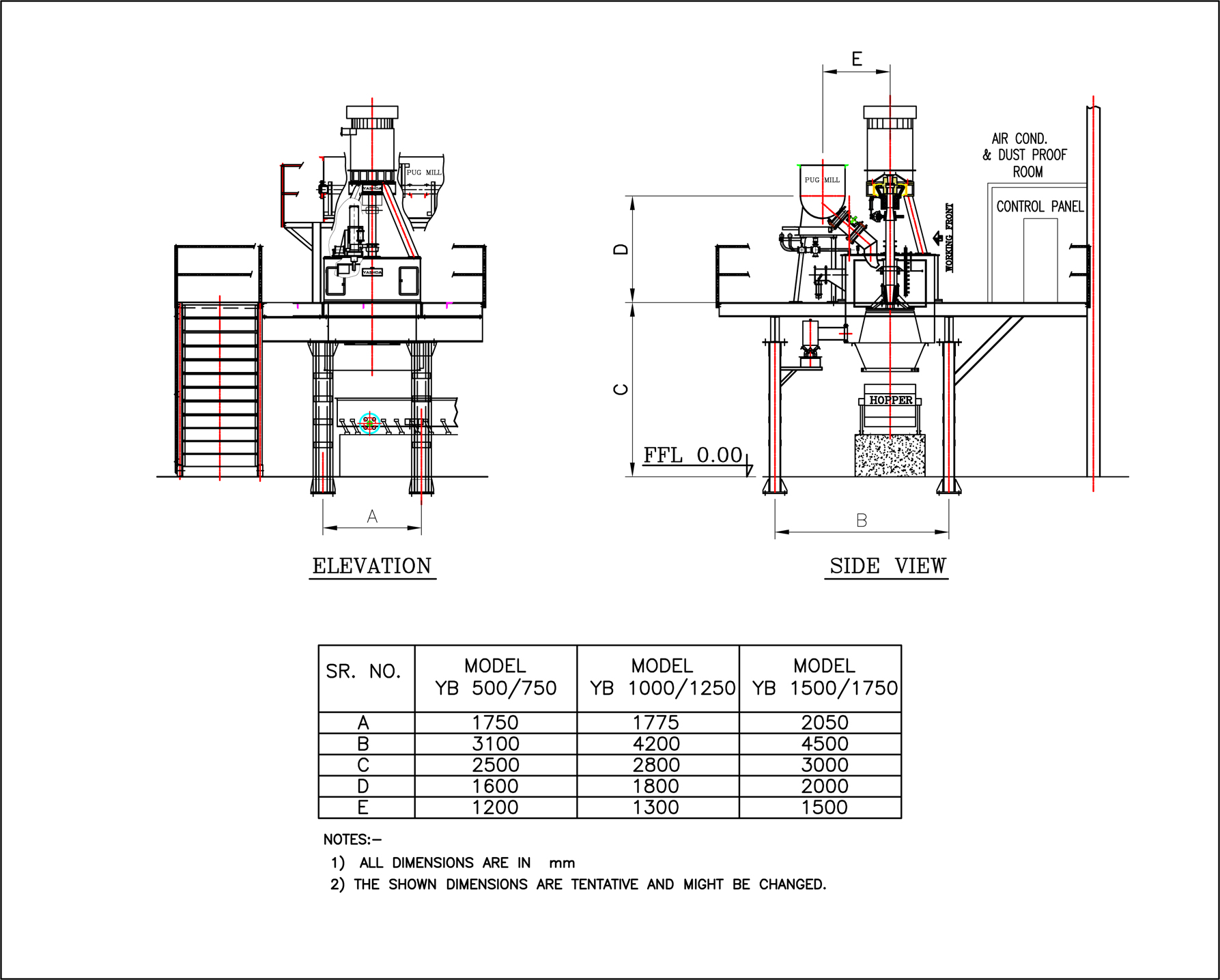

Typical Installation Layout For Batch Type Centrifugal Machine