Dynamic Balancing

Dynamic balancing is a way of balancing machines by rotating parts quickly and measuring the imbalance using electronic equipment.

The imbalance measured can then be corrected by adding or subtracting weight from the rotating parts until the vibration is reduced. Basically, all machines have some form of residual vibration. Enormous vibration in rotating machinery can cause high levels of noise and more importantly.

Balancing of Rotating machinery is an essential manufacturing operation in all segments of every industry. An unbalance component in rotating condition will lead to VIBRATIONS & STRESSES in the assemblies. Hence dynamic balancing becomes a vital operation for every rotary component.

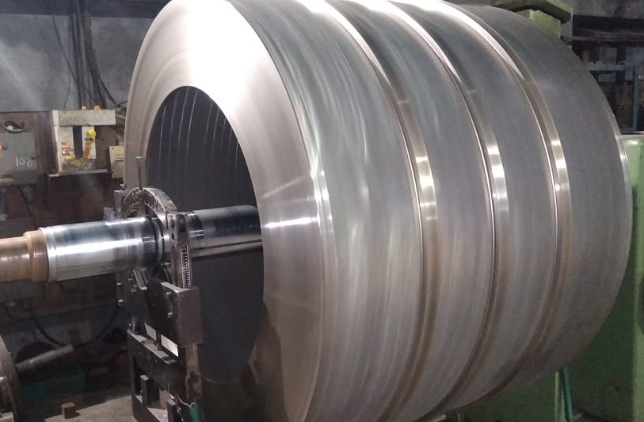

We do the balancing of any make and any type of centrifugal basket, product distributor assembly, drive and driven pulley etc. within 5 gms. at 600 RPM

Benefits of Components Balancing

- Vibration Reduction / Elimination

- Increased Rated Speed / Performance

- Noise Reduction / Quality Improvement

- Extended Rotor Life

- Reduces Structural Stress

- Decrease Operational Cost

- Operator Safety

- Lowers Energy Costs / Power Saving

- Extended Bearing Life

- Improve Working Conditions

- Avoid Production Loss / Break Downs