CONTINUOUS TYPE CENTRIFUGAL MACHINES

The continuous centrifugal machine is a vertical operating machine with the basket driven by energy efficient 3-Phase T.E.F.C. Squirrel cage induction motor from below, through a “V” belt transmission. All rotating parts are housed in the inner casing. The outer casing and massecuite feed pipe are so designed & located, as to prevent any ingress of cold air, thereby helping centrifugal separation, particularly for high viscous massecuites. Inner casing is specially designed, reinforced rubber buffers located at appropriate positions ensuring smooth, sturdy & safe centrifugal operation.

We offer a wide range of machine models ranging from 850mm to 1500mm basket dia. with technical specifications as under,

|

PARTICULARS

|

MODEL YK 850

|

MODEL YK 1100

|

MODEL YK 1500

|

|---|---|---|---|

|

Diameter of Housing (mm)

|

1750

|

1900

|

2350

|

|

Overall Height (mm)

|

965

|

1325

|

1385

|

|

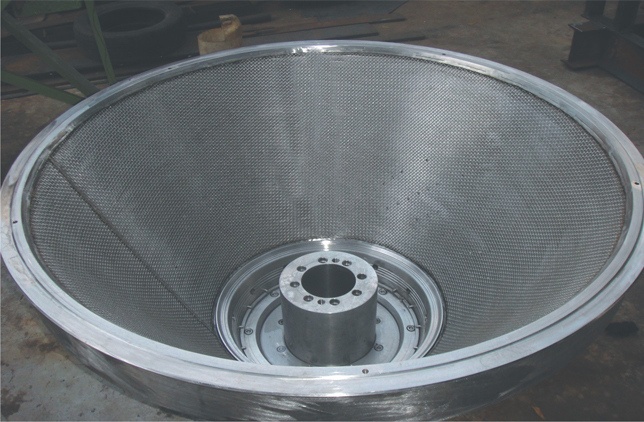

Inside Diameter of Basket (mm)

|

850

|

1100

|

1500

|

|

Basket Cone Inclination (degree)

|

30

|

30

|

30

|

|

Basket Material Specification (moc)

|

Special high tensile strength resistance, special chloride resistance, anti-corrosive & food grade stainless steel quality material.

|

||

|

Basket Speed (rpm)

|

1800/2000

|

1800/2000

|

1550/1680/1730

|

|

Installed Motor Rating (kw)

|

37

|

55

|

90

|

|

Effective Screening Surface Area (mm2)

|

11200

|

14500

|

23200

|

|

Max. Centrifuge Effect (g)

|

1900

|

2469

|

2352

|

|

Machine Lubrication System

|

Bearings are lubricated by Grease/Oil mist lubrication to ensuring low bearing temperature rise.

|

||

|

Capacity of Machine

|

|||

|

“C” Massecuite

(TPH with 0.06 mm screen aperture)

MODEL YK 15006

|

4 to 6

|

6 to 8

|

10 to 12

|

|

“B” & “C” After worker Massecuite

(TPH with 0.09 mm screen aperture)

|

6 to 8

|

10 to 12

|

18 to 20

|

|

Affination Products

(TPH with 0.09 mm screen aperture)

|

8 to 10

|

13 to 15

|

20 to 22

|

Capacity subject to screen aperture, massecuite quality, temperature & requirement of process results etc.

The above machines can also be supplied in SS construction of food grade quality.

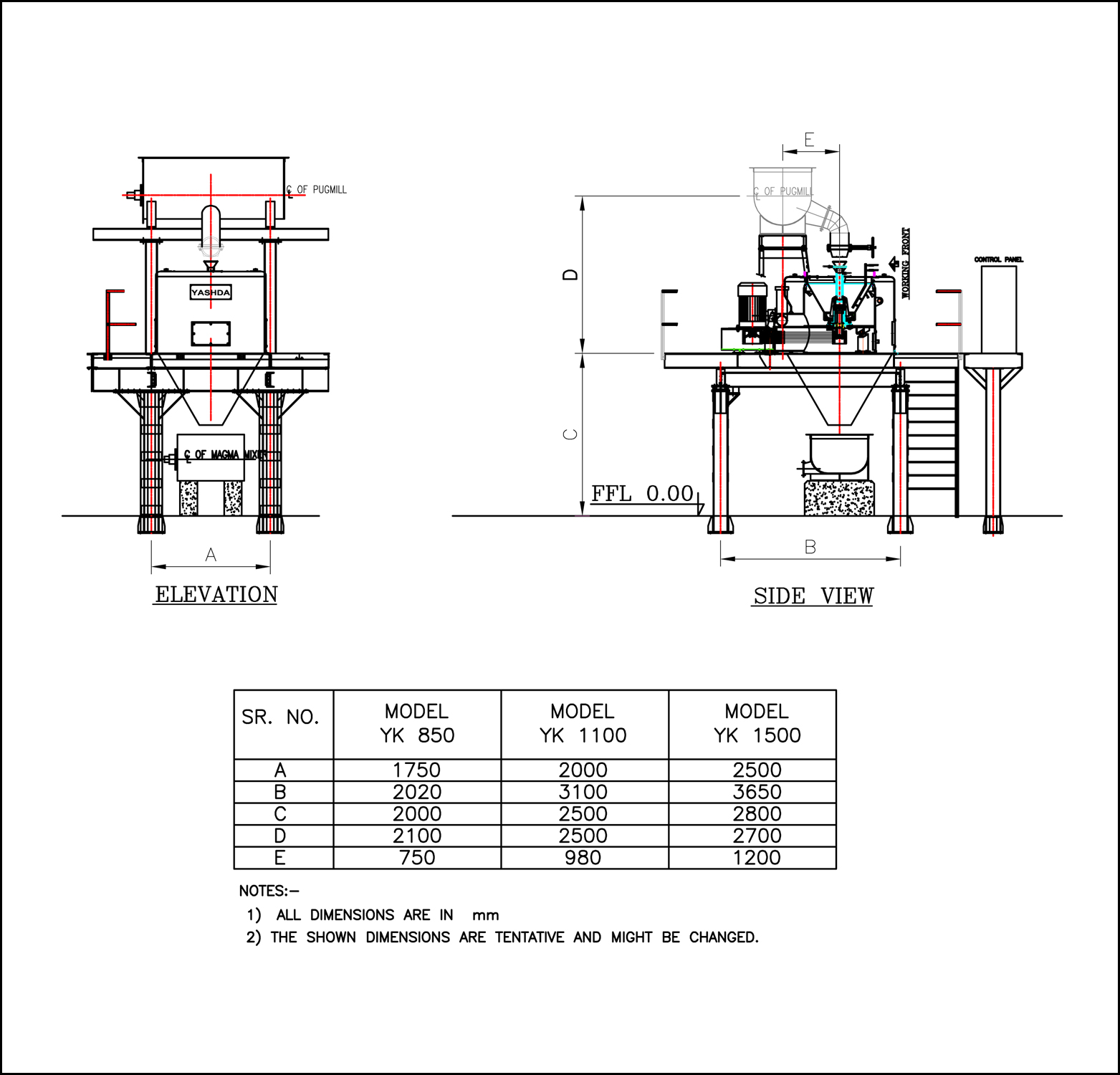

Typical Installation Layout For Continuous Centrifugal Machine